In the previous topic, you created a tree diagram. Key issues identified must also be sorted in the order of their importance. A prioritization matrix helps determine the order for dealing with different issues or selecting solutions according to their relative importance. In this topic, you will create a prioritization matrix to identify crucial issues that require immediate attention.

You must prioritize key issues identified according to their importance to determine which issues or solutions are the most critical and need to be addressed first. Using a prioritization matrix, you can determine such crucial areas where Six Sigma projects need be implemented to improve your business processes.

What are Prioritization Matrices?

A prioritization matrix is a tool used for determining the most important issues or solutions. This tool can be used for any prioritization activity. In a Six Sigma project, it can be used for filtering or prioritizing either causes or solutions. For example, the cause-and-effect matrix is a prioritization matrix used for prioritizing causes, while the criteria-based matrix is used for prioritizing solutions.

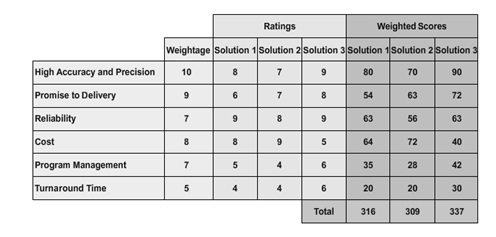

Whatever the matrix, the procedure used for prioritization is the same. The Six Sigma team identifies different criteria to be used for measuring different solutions. The relative importance of each criterion is determined and a numerical value indicating the weight of each criterion is entered in a column. Ratings are then assigned to the solutions against different criteria. The different solutions are scored against the identified criteria. Each rating is then multiplied by the criteria weights to obtain the weighted scores. The weighted scores are then added to find the cumulative value. The option with the highest total value is regarded as the option with the highest priority.

Fig: A sample prioritization matrix

What are the use of Prioritization Matrices?

- Prioritizing complex issues involving several criteria against which the issues are assessed.

- Assigning scores to the criteria or issues when data is available.

- Choosing key areas to be focused upon immediately.

- And, garnering team support and approval of crucial issues.

How to Create a Prioritization Matrix?

To create a prioritization matrix for determining key areas where Six Sigma projects need be implemented first:

- Gather the team members required to participate in the exercise.

- It is not necessary to limit the team to only the project team members.

- Involve all stakeholders who would have influence on the items to be prioritized.

- Ideally, the size of the team should be around eight.

- Agree upon the scope and the duration of the exercise because there is a tendency to drift from the main subject of interest, which may consume more time.

- Identify criteria against which the items to be prioritized can be weighed. Select the criteria according to your business and the nature of the process.

- Assign weights to the criteria on a scale of 1 to 10.

- Use an ascending scale while assigning the weight. Usually, the higher the better.

- Draw consensus within the team on the weights.

- Assign ratings for each item to be prioritized against different criteria on a scale of 1 to 10. Alternatively, the team can also pick solutions one by one and gather votes for each criterion. Members who agree that a solution fits a particular criterion vote for it. Ensure that necessary information is available to the team before voting.

- Compute the total score for each item.

- Multiply the rating for an item by the weight.

- Add the total scores for each item.

- Continue doing this for every criterion of all the items.

- Shortlist the items with higher scores for implementation.

Tags

Have you ever confronted a situation doing hard work the whole day and at the end you realize that most of the time had been given by you and your team to the Non Value Added things!

One of the important aspects of the leadership in today’s competitive world is Prioritization. It helps to save time and money as you will be able to focus on what is important at the expense of lower value activities. Prioritizing skills are your ability to see what tasks are more important at each moment and give those tasks more of your attention, energy, and time.

We all have so much on hand to do and really speaking so much time to finish the things up. But we lack the skill to manage our work with the time. We mostly forget to take up the important things first and less significant work later. Instead, we do completely opposite to this. This is human nature as we all do the same thing in our day to day lives.

This issue is pertinent not only at an individual level, but even at organizational level. Organizations focus on the wrong reasons or causes and waste a lot of effort to solve a problem or improve their business.

How to improve upon it?

Lean Six Sigma teaches a very useful technique of prioritization to overcome this problem which is a mother of our all the other problems.

Pareto Analysis is based on 80/20 rule which says that our 20% efforts (out of the whole 100%) will give 80% of the benefits. This can be interpreted in many different ways like, for sales people 80% of the orders will come from the 20% of the customers, for team managers 20% people of the whole team shall give 80% of the work or results. Here, we should keep in mind that this doesn’t mean that the rest 20% is not important at all but can be said as less significant.

To generalize, 80% of the problem is caused by 20% of the reasons!

Thus using the Pareto principle, we can derive maximum impact with minimum effort and within short time span, if we focus on the right factors. Simple it is, right?

Before understanding the benefits of Pareto Analysis there are certain facts to be known about it. They are as under:

- This principle was developed in the year 1896 and is named after Vilfredo Pareto who was an Italian engineer, sociologist, economist, political scientist, and philosopher.

- Pareto derived this concept by his work and experience and observed that 80% of the wealth in Italy belonged to 20% of the people.

- In the year 1941, Dr, Joseph Juran who was an evangelist of quality and quality management as he was an engineer and a management consultant cam across the concept of Pareto Principle. He then started applying the principle in the quality and derived a phrase through experience that is “there are vital few and useful many”.

- The Pareto Principle can be implemented in many different aspects such as in science, management, business, in software, in sports, occupational health and safety, financial service industry, and implementing projects which says that put 80% of your time in 20% of your project which will save a lot of your time and energy.

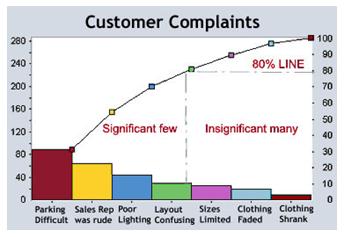

- Pareto principle can be graphically represented by Pareto Chart that contains bothbars and a line graph, where individual values are represented in descending order by bars, and the cumulative total is represented by the line.

With an example given as under you will be able to understand why to focus on significant few:

Our Online Lean Six Sigma Green Belt Certification course teaches you step by step procedure to construct a pareto chart, different pareto variants and how to interpret them. More importantly it covers when and when not to apply pareto principle.

Benefits of Pareto Analysis:

- Improved Decision Making: With a focus on resolving problems, the procedures and processes required to make the changes should be documented during a Pareto analysis. This documentation will enable better preparation and improvements in decision making for future changes.

- Increased Efficiency: Once the changes or problems are listed, they are ranked in order from the biggest to the least severe. The problems ranked highest in severity should become the main focus for problem resolution or improvement. Focusing on causes and problem resolution contributes to organizational efficiency.

- Enhanced Problem Solving Technique: Members of a group can conduct a Pareto analysis together. Arriving at a group consensus about the issues that require change fosters organizational learning and increases group cohesiveness. Lean Six Sigma Green Belt Certification course shall help the individuals of the company learn many tools along with Pareto Analysis which shall also help him or her to boost their careers.

- Saves Time and Money: Doing right things at the right time with right people and at the right place is naturally going to save time and money and this has to be calculated by multiplying the time with the number of individuals involved in the process.