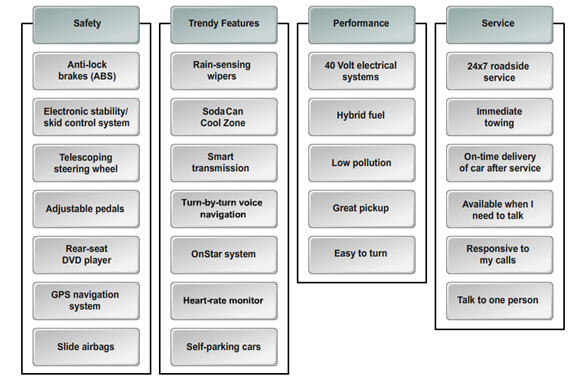

An affinity diagram is a tool that is used to organize a large number of ideas, opinions, and issues and group them based on their relationships. Affinity diagrams are generally used for categorizing ideas that are generated during brainstorming sessions and can be particularly useful for analyzing complex issues.

The steps for creating an affinity diagram can include:

- Generating ideas through brainstorming.

- Displaying the ideas randomly.

- Sorting the ideas into groups.

- Creating header cards for each group to capture the essential links among the ideas in each group.

- And, drawing the affinity diagram by writing the problem statement at the top and the headers with their respective groups of ideas below the problem statement.

- An affinity diagram helps in sorting and grouping customer requirements.

Tags

To gather the VOC, effective methods for accurately capturing customer requirements are required. Several methods are available to capture the VOC.

- Interviews are used to gather information from stakeholders by talking to them directly. Interviews aid in identifying and defining features and functions or desired project deliverables.

- Focus groups is a trained moderator-guided interactive discussion that includes pre-qualified stakeholders and subject-matter experts (SMEs) to elicit their expectations and attitudes toward the proposed product, service, or result of the project.

- Facilitated workshops is an interactive group-focused sessions that bring together key cross-functional stakeholders to define the project or product requirements. It is a primary technique to define cross-functional requirements and reconcile stakeholder differences to the project. Facilitated workshops occur much faster than individual discussions.

- Questionnaires and surveys is another method where written sets of questions designed to quickly gather information from a broad audience.

- Mystery shopping commonly performed in retail industries. This method is used to measure the quality of a service by gathering specific information about the product or service. This method is performed by mystery shoppers who introduce themselves as customers and perform specific customer-related tasks, such as purchasing a product and raising questions and complaints about the product.

- Observations are a direct way of viewing individuals in their work environment or while using the product to identify the project or product requirements. Also referred to as job shadowing.

- Market research is an organized effort to gather information about the current trends in an industry and also Field reports is a formal report documented by field engineers or other on-site personnel who gather required information about events that occur during their field work.

- Customer feedback and complaints data are used to gather customer requirements. This method also involves gathering customer feedback about the quality of a product or service. The consolidated list of feedback from customers is referred to as complaints data.

- Reliability data is a source of information that helps in analyzing the reliability of a product or process. By gathering this data, you can plan strategies to gain a reputation with customers as a reliable provider of services.

- Staff feedback is another method of gathering opinions from staff who interact with customers directly or who possess knowledge about customers and their expectations. This information is captured by conducting surveys, brainstorming sessions, and other information gathering sessions.

Tags

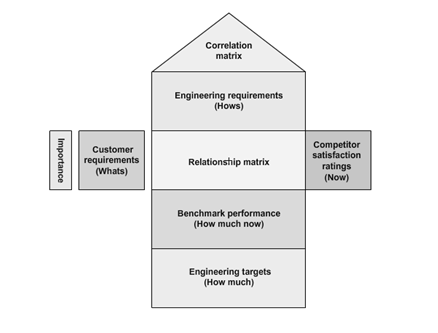

Quality Function Deployment (QFD) is a structured approach followed by customer-driven organizations to transform customer requirements into their product specifications.

The House of Quality (HOQ) is a diagram used by a product development team during the initial stage of the QFD process.

It uses a planning matrix to define the relationship between customer requirements and the capability of the product and the company to satisfy these requirements. Because this matrix looks like a house, where customer requirements and product attributes resemble the main living quarters, competitive analysis resembles the porch, and the correlation matrix resembles the roof, it is called House of Quality.

HOQ encompasses different QFD elements used for understanding customer requirements and aligning business processes to meet these customer requirements.

It starts with customer requirements. The customers for a product or service are identified and their requirements from the product or service are gathered using different tools such as focus groups, surveys, and customer experiences. A structured list of customer requirements is then drawn by analyzing and organizing this data using tools such as affinity diagrams and tree diagrams.

Importance ratings are used for quantify the customer requirements and rated according to their importance on a scale of 1 to 5. This rating will be used in the relationship matrix at a later stage.

Another element is the Competitive analysis where customers views about the competition are gathered through research to provide a better understanding of the market. Here, the customers rate an organization’s products or services against competitors’ products or services. Also, Technical requirements that are not known to customers are identified and documented. These requirements generally stem from management or regulatory standards that a product must meet.

Relationship matrix defines the relationship between customer requirements and an organization’s ability to meet those requirements is determined. The relationship between the two factors is classified as weak, moderate, or strong and given the values of 1, 3, and 9, respectively. Even, in Importance weighting rating, Customer requirements are weighted according to their importance for defining and prioritizing key criteria. The relative importance of customer needs and the company’s and competitor’s performance are taken into account while calculating this. Target values for each product or service attributes, known as technical descriptors, that can be used as benchmarks against competitors’ target values are established. These target values are the “how much” of these product or service attributes.

The technical descriptors are compared with the competitors’ technical descriptors using scientific analytical techniques to assess their properties is called Engineering analysis. This also includes reverse engineering competitors’ products or services to determine the values for their technical descriptors. Correlation matrix is the relationship among customer requirements are analyzed to identify correlated requirements. The relationships are then ranked for determining areas of improvement that need to be focused upon.

Tags

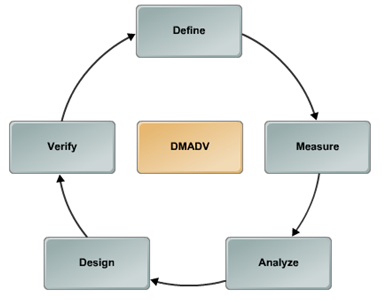

Another roadmap of DFSS is DMADV, an acronym for five interconnected phases, namely Define, Measure, Analyze, Design, and Verify. This methodology is used in projects that involve creating a new product or process design.

Define – The project goals are defined so that they are in line with customer requirements and enterprise strategies.

Measure – Characteristics that are critical to quality as well as product and process capabilities are measured.

Analyze – The different process options are analyzed and the best process that is consistent with customer requirements is selected.

Design – The details of the process are designed and optimized to meet the needs of customers followed by the performance of the new design which is tested through pilot runs before implementation.

Verify – In this phase the results are test and implementation of new design is carried out for large scale deployment.

Tags

While the deployment of Six Sigma depends on several factors; the following approach explains Six Sigma process in its simplest form.

Six Sigma as a management discipline puts customer’s interest ahead of others. The process of gathering customer requirements is called as Voice of Customer (VOC). A good deployment program starts with VOC. Customer requirements directly translate into business performance standards. In Six Sigma and many quality management approaches, these performance standards are called as Customer Specification Limits.

Operational metrics and performance measures like KPIs are created based on customer requirements. Such operational measures or KPIs are called as Critical To Quality (CTQ) metrics in Six Sigma.

Output of existing processes is measured against customer requirements. This becomes a benchmark of performance. In Six Sigma, this step is called as Assessment of Current Process Capability.

In case an end-to-end process is not capable of consistently meeting customer requirements, and produces high volume of defects; it is taken up for improvement.

Process improvement approach used in Six Sigma is called as DMAIC. It is the acronym of Define, Measure, Analyze, Improve and Control: a 5 step improvement approach.

In this manner, Six Sigma aims to link Customers, Business Processes, CTQs and process improvement all together.

The real power of a Six Sigma Process is in consistently and iteratively following the above activities.

Thus, an organization following a Six Sigma Process:

- Systematically and regularly gathers VOC

- Measures its process capability

- Identifies improvement opportunities

- Uses DMAIC to improve its processes

Tags

This is the second article in the series that will help understand ‘What is Six in Six Sigma?‘ If you haven’t already read our article ‘What is Sigma in Six Sigma‘, we would like to recommend that you first do so.

For now, let’s look into what is Six in Six Sigma.

Let’s get started by understanding Customer Requirement and Actual Performance.

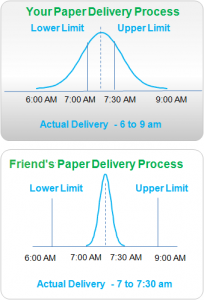

We are going to use the example of newspaper delivery everyday to your house. As a customer, you want newspapers to be delivered between 7:00 and 7:30 am (say within a half hour window). However, in reality, the paper gets delivered only between 6:00 to 9:00 am (a 3 hour window). So, in this case, the customer requirement or allowable variation is ’30 mins’ while the Actual Performance or Actual Variation is 3 hours.

On the contrary, your friend isn’t so particular about his newspaper delivery. He is in fact fine if they are delivered between 6:00 to 9:00 am (a 3 hour window). But in reality, his papers get delivered between 7:00 to 7:30 am (a half hour window).

How would you characterize these two situations?

- In your case, actual variation is much higher than allowable customer requirement. In ot

her words, Standard Deviation or Sigma is high.

her words, Standard Deviation or Sigma is high. - In your friend’s case, actual variation is much lower than allowable customer requirement (and so, Standard Deviation or Sigma is low)

Now, let’s answer the question ‘What is Six in Six Sigma?’

Six refers to the Sigma Capability of any process. In this case, the newspaper delivery process. When it’s Six, it means that the Standard Deviation or Sigma is so small that 6 Standard Deviations or 6 Sigmas can be fitted on either side of the bell-shaped curve. Based on the principle of bell-shaped curve (normal curve), 6 Sigma equals only 3.4 defects per million opportunities. For the newspaper example, it means that if there are 1 million days of newspaper delivery, only on 3.4 days (i.e. 3 or 4 days) of the delivery will be beyond your requirement. So, it is very obvious that your newspaper delivery isn’t at the Six Sigma level, but your friend’s delivery could be. It depends on the value of Standard Deviation. We covered the computation of standard deviation in ‘What is Sigma in Six Sigma’.

Let’s say for your friend’s process, only 5 standard deviations or sigmas can be fitted on either side of the bell-shaped curve, then, his sigma capability is at 5 or his newspaper delivery process is at 5 Sigma.

To sum up, if you want a particular process to be at Six Sigma, then you will have to manage the following:

Understand what the customer requirement is? If there is a window within which the customer wants her delivery or quality, then that becomes your customer requirement.

- Use the data of process performance to compute the standard deviation.

- Assess if the Standard Deviation or Sigma of the process is small enough, that 6 Sigmas can be fitted on either side of the customer requirement window.

- Let’s say your process isn’t at Six Sigma then to find out the sigma value you can either use Sigma Capability Table, Normal Distribution Table or Sigma Calculator. Details of how to compute Sigma for any process is covered in detail in our Six Sigma Green Belt Course.