Cpm is yet another interesting process capability metric that is not very popular. In fact it is more robust than Cpk.

Cpm is an advanced measure and it corrects some deficiencies in Cpk. It is also called as Taguchi Capability Measure. In order for us to understand Cpm, let’s take a step back and understand Cpk.

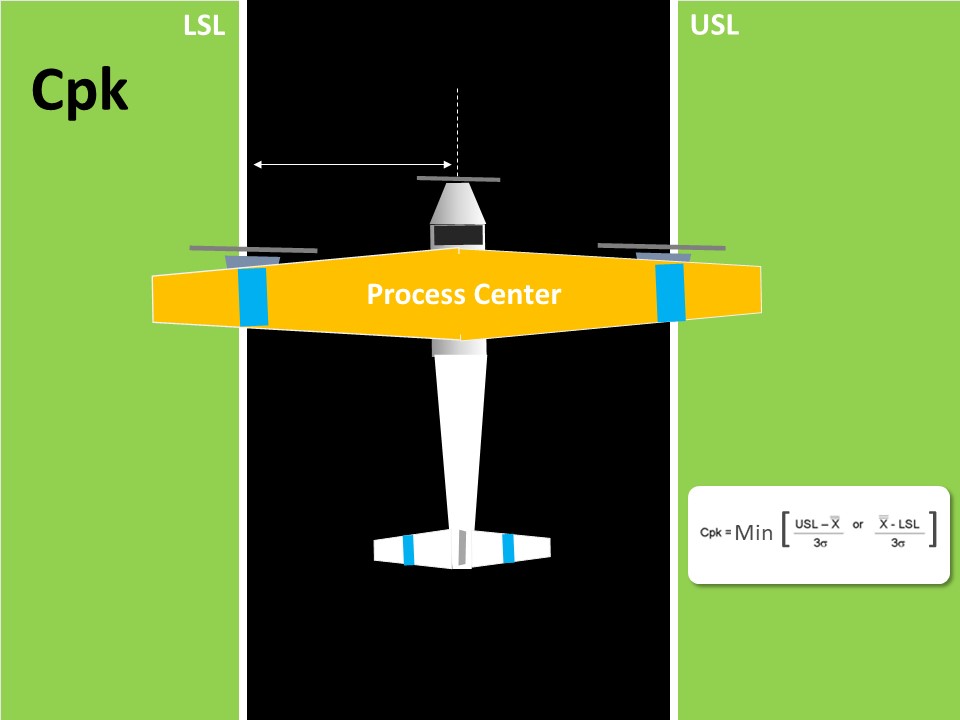

Cpk

Cpk is considered as a measure of the process centering. If you closely observe the Cpk formula, it doesn’t take the actual Target value. Target Value is the center value obtained from customer specification.

However it takes the lowest value of (USL – Process Mean) and (Process Mean – LSL). In a way, this is an indirect method of assessing if the process centered to the tolerance.

As an analogy, in order to know if the plane is landing exactly on the middle of the landing strip, we look at the distance of the plane’s nose from either edge of the strip. That is good but it’s only an indirect way of assessing the process center.

Now it’s look at Cpm and then draw comparisons.

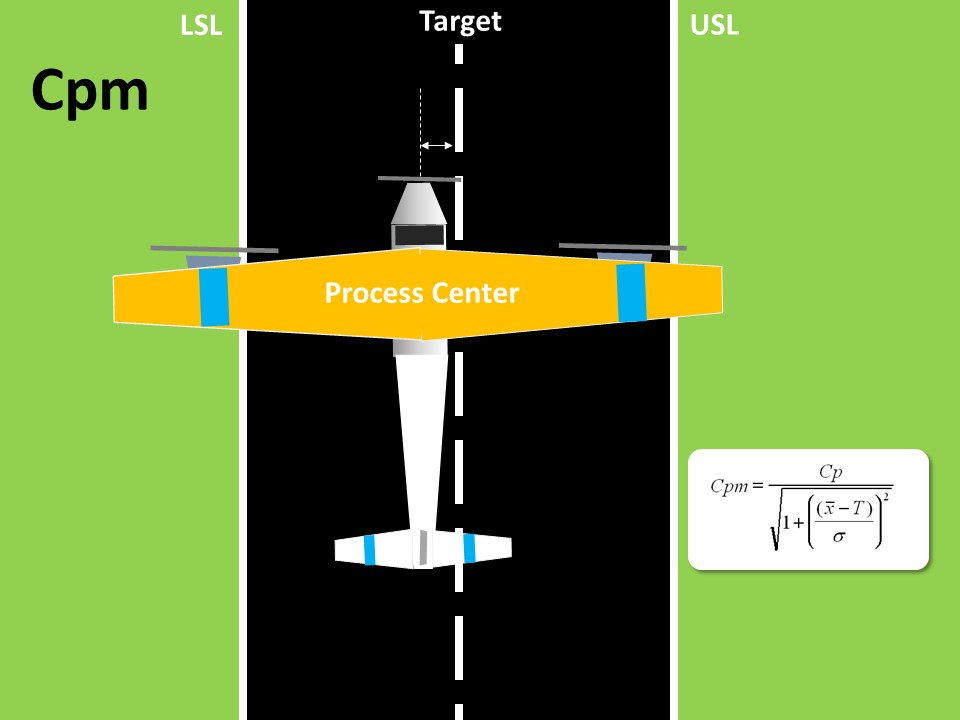

Cpm

If you look at the formula of Cpm, it contains the target value. Thus in addition to obtaining the USL and LSL from the customers, we also obtain the Target value.

This means, Cpm is a true process centering capability index, because it compares the difference between process mean and target value. To draw an analogy to plane landing, we are comparing the plane nose to the median line of the strip.

Let’s now take a few scenarios to compare Cpk and Cpm values.

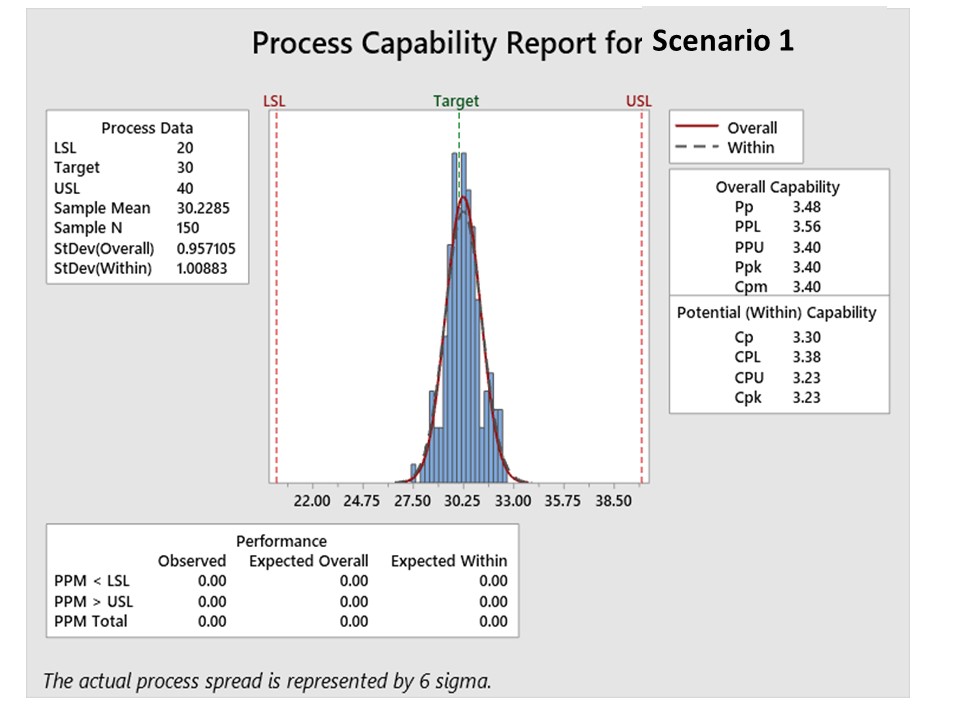

Cpk and Cpm Scenario 1

Process is centered, mean and target are close to each other. Cpk and Cpm are high and nearly the same.

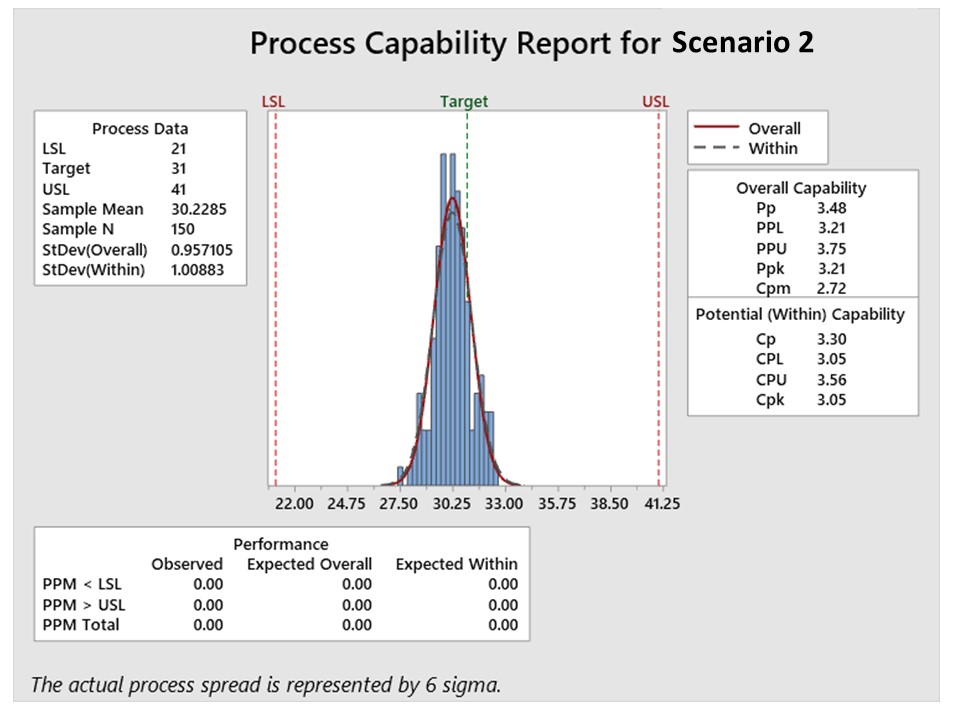

Cpk and Cpm Scenario 2

Process is not centered and Cpk & Cpm both have reduced.

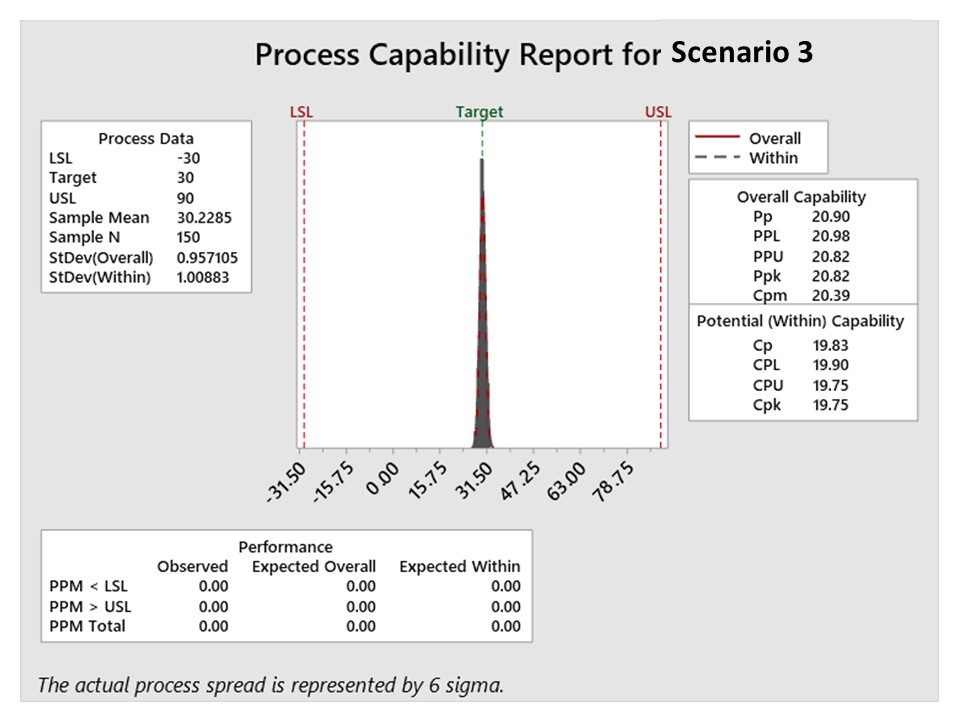

Cpk and Cpm Scenario 3

Process is centered but tolerance is liberal. Thus Cpk and Cpm values are very high.

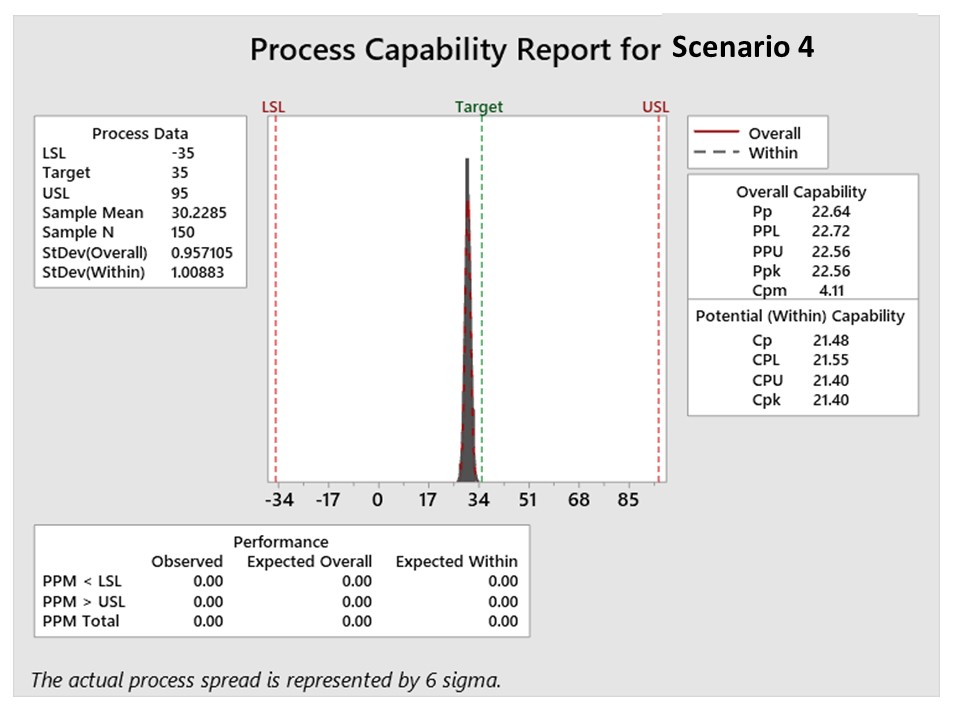

ScCpk and Cpm Scenario 4

Out here, the process has liberal tolerance but a meagre shift from the target. In this scenario Cpk value hasn’t really dropped much, but Cpm has crashed down. While this example is an extreme scenario with very liberal tolerance, it’s meant to illustrate the fact that Cpm is very sensitive to even small shift in mean from center, while Cpk isn’t.

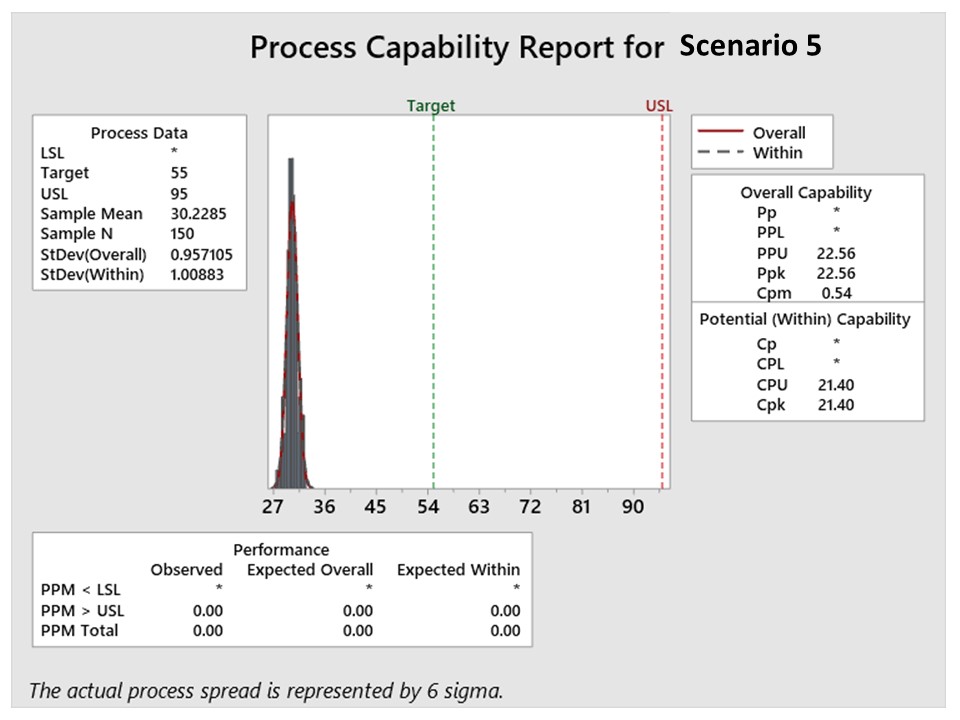

Cpk and Cpm Scenario 5

In this case, there is only a specification on one side. In most business processes, Service Levels have only an upper or lower specification. In some cases, Cpk looses its significance. However, in all service scenarios, there is a target value. For ex: customers are told that payment will be updated in 4 hours but the internal target is to get it done in 2 hours. Process is capacitized for 2 hours. In also such scenarios Cpm will be a relevant centering metric.

In this scenario, Cpk is high but Cpm isn’t. This Cpm is a good capability measure for one sided tolerances.

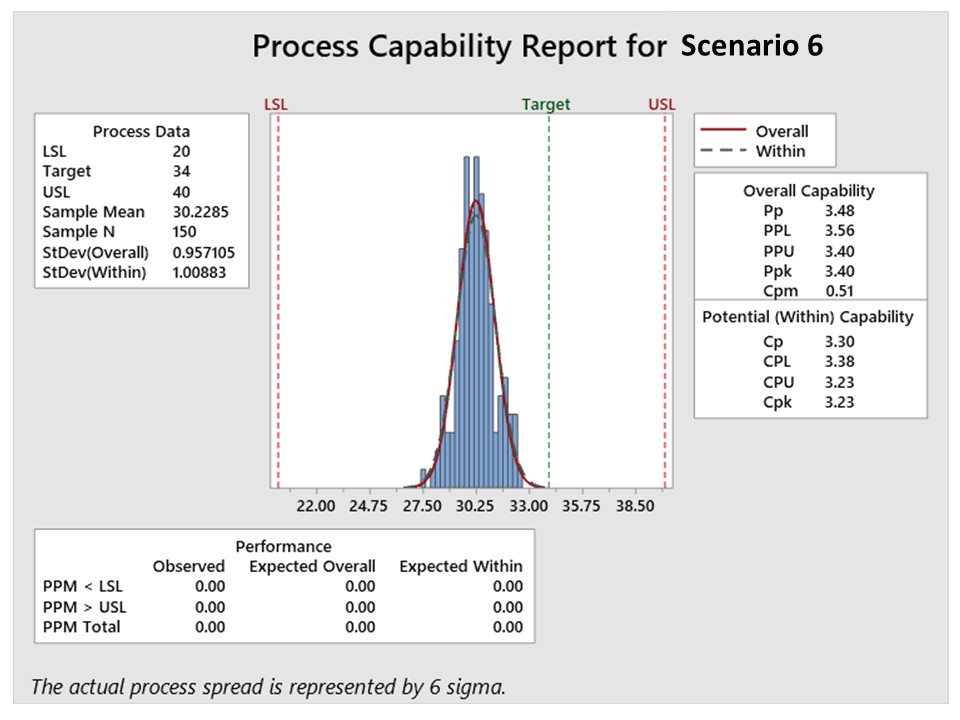

Cpk and Cpm Scenario 6

This is a unique case, where the Target isn’t the center of tolerance. This situation can occur in process industries and for certain critical dimensions where we intentionally set the process not at the center but to one side (such as to offset for tool wear in grinding).

From the above 6 scenarios, it is clear the Cpm is a robust process centering capability index which can be used to evaluate process shifts, drifts, one-sided specifications and non-centered specifications.

To further get some hands-on practice, try drawing the following values in paper and then calculated CpK and Cpm.

usl = 30, lsl = 6, Target = 18, Mean = 10, SD = 0.6